EcoNautic Systems GmbH

Brauereistraße 15

D-17159 Dargun

Tel.: 49 39959 251-0

Fax: 49 39959 251-10

Quality capability – because trust begins with precision

At EcoNautic Systems, quality is not a coincidence, but the result of structured processes, technical diligence, and a commitment to responsibility. As a manufacturer of complex components and assemblies, we know that only those who consistently focus on quality can survive in the long term – and gain the trust of their customers.

That's why we work according to a certified quality management system that not only meets standard requirements but also actively contributes to the improvement of our products and processes.

Certified processes – traceable and auditable

Our quality management is based on internationally recognized standards:

- DIN EN ISO 9001 – Quality management for industry and production

- DIN EN 9100 – specifically for aviation, space and defense

- IATF 16949 – Standard for the automotive industry and its suppliers

These standards define clear requirements for our internal processes – from planning and production to delivery and documentation. Regular audits and training ensure that these standards are implemented and practiced throughout the company.

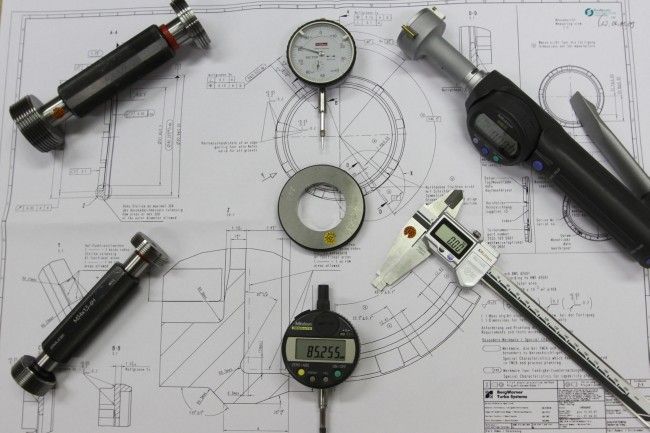

Modern tools for targeted quality assurance

For operational implementation, we use a powerful CAQ (Computer Aided Quality) system, which allows us to systematically plan, document and monitor quality assurance measures.

Proven methods are used in advance quality planning, such as:

- APQP (Advanced Product Quality Planning) – for structured project planning

- FMEA (Failure Mode and Effects Analysis) – for early failure prevention

- Poka-Yoke – to prevent errors directly at the workplace

These tools enable us to plan production proactively and continuously improve our processes – with the clear goal of ensuring our customers’ long-term satisfaction.

Non-destructive testing – security that goes beneath the surface

Particularly stringent requirements apply to the production of welded assemblies, which often fulfill safety-relevant functions. To test the quality of these components, we rely on various non-destructive testing (NDT) methods that enable inspection without damaging the material.

Our testing expertise includes:

- Radiographic testing (RT): carried out in cooperation with TÜV NORD to reliably detect internal defects

- Penetrant testing (PT): by our own certified personnel, ideal for fine surface cracks

- Visual inspections with video endoscopes: specifically for cavities, with flexible probes of 2–4 mm diameter

- Pressure and leak tests: on in-house test benches, exactly according to customer specifications

These procedures are an integral part of our quality system and can be documented upon customer request – an important component of our transparent and reliable delivery capability.

Quality as an attitude

What makes us special at EcoNautic is our holistic approach to quality: It doesn't start with the final inspection, but rather with the selection of materials, employee training, and the structured planning of each order.

Our goal is clear: technically flawless products that are delivered on time – and function long-term. Our name, our team, and our location in Dargun stand for this.